We use cookies

Using our site means you agree to the use of cookies and similar technologies. Read about our policy and how to disable them here

Improving safety for fencers is one of the FIE’s main roles as a governing body.

Huge steps have been made over the last 30 years to increase safety, starting with the implementation of both FIE level protective clothing and the lower level 350 newton testing standard. This is an ongoing process and has led to many improvements in safety, including:

It is little known that to further increase safety at some elite events, blades are also tested for cracks prior to the events. This mainly happens at the Olympics and World Championships where the speed and power of the fencers has the perceived greatest risk of injury from a broken blade.

The current tests uses a coil which the blade is passed through and this performs an ‘eddy test’ https://en.wikipedia.org/wiki/Eddy-current_testing

This basically looks for fluctuations in the magnetic field which can indicate the presence of a micro crack in the blade. Blade failures all occur at the position of a micro crack and so it is possible to predict failures before they occur. Practical testing like this can allow the event organisers to reduce the chances of a blade breaking during use.

Testing in a coil is a good start, but we wanted to look into this in more depth to find out if there was anything better. We invited testing experts who normally work in fields such aviation and the gas pipe industry to visit us and show us the kinds of systems that were being used in other industries to predict failures before they can occur.

They explained that passing a blade through a coil was a reasonable way to predict micro cracks, but was limited in its accuracy. To test something accurately by passing it through a coil, the part needs to be of a uniform cross section and the coil needs to match that cross section. In fencing where the blades are tapering this is impossible. So although this type of analysis can give some indication, it is not very accurate.

They demonstrated a pen type eddy test where you pass a probe along the blade to do a similar test, but as the probe is touching the blade it is far more accurate. The problem with this approach is that you have to do both sides of the blade and it is very time consuming.

We continued to research looking for something that was faster and maybe something that could test the whole blade at once, and we came across magnetic particle inspection. https://en.wikipedia.org/wiki/Magnetic_particle_inspection.

This is an entirely non-destructive test where you magnetise the piece of steel and then apply a magnetic UV reactive dye. The dye is pulled into any cracks and then can be clearly seen under a UV light.

You can see an interesting video of it here

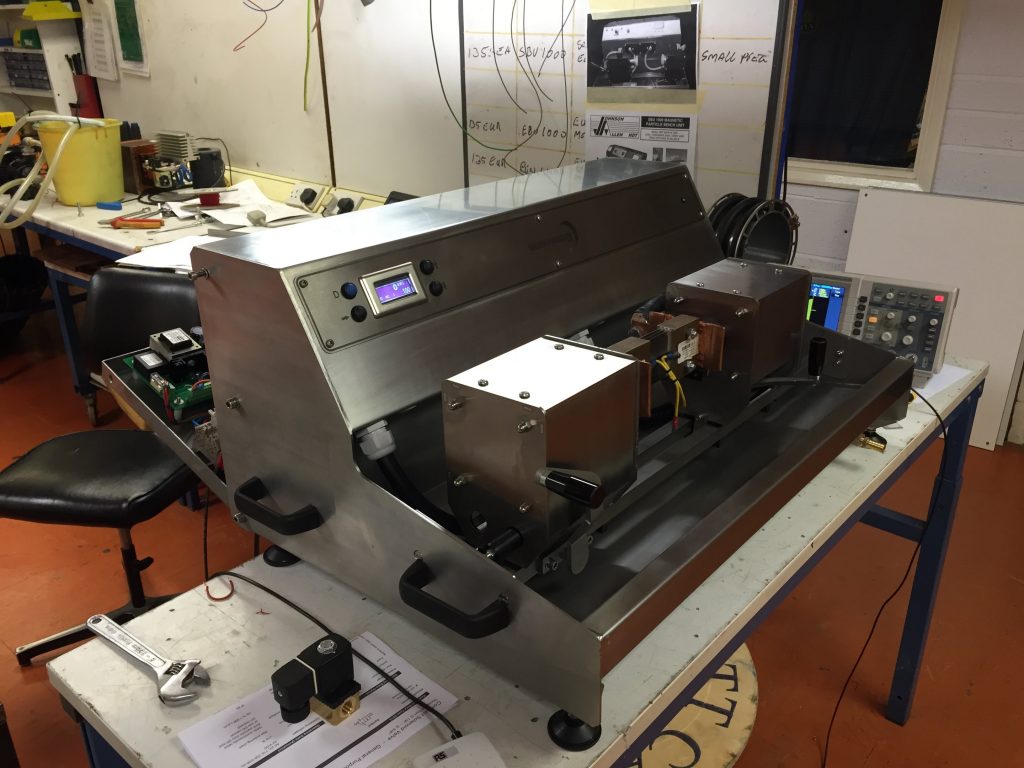

We sent off some blades to test and the test rig supplier were able to clearly able to demonstrate that the entire blade could be tested very quickly and micro cracks were immediately visible:

The cost for a suitcase sized test rig is around $8000 so we believe that this kind of testing could be used to significantly improve safety at high level fencing events.