We use cookies

Using our site means you agree to the use of cookies and similar technologies. Read about our policy and how to disable them here

Hi Fencers! Danielle here, product development intern at Leon Paul. As of September, I have been working here, undertaking a 9-month placement as part of my sandwich year at university. I am currently reading Sports Engineering at Nottingham Trent University and am very fortunate that Leon Paul offered me this perfect opportunity to learn more about the engineering behind sports equipment in a work environment.

I myself am a fencer, I have been competing now for 10 years and this knowledge of the sport has been very helpful when looking at improving products. I have been working on a multitude of TOP SECRET projects watch this space!

For me the most interesting project that I have been trusted to work on at Leon Paul is the women’s chest protector. Now before I lose half of the readers who this product probably won’t be of much interest to, hold on, I may be able to peak your interest with some pretty cool materials and technology.

My relationship with my chest protectors has been very on and off. On one hand it isn’t very comfortable, not very attractive and can slightly restrict your mobility however it does provide the protection I need to not get hurt, with the confidence that I am protected whenever I fence.

So, over the summer my university had an opportunity for me to take place in an EROS research project titled “Fabrication of Auxetic Meta-Materials using SLA 3D Printing”

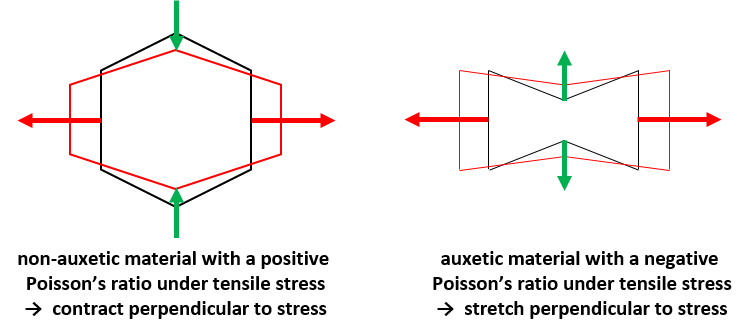

The definition of Auxetics is “…. structures or materials that have a negative Poisson’s ratio. When stretched they become thicker perpendicular to the applied force”

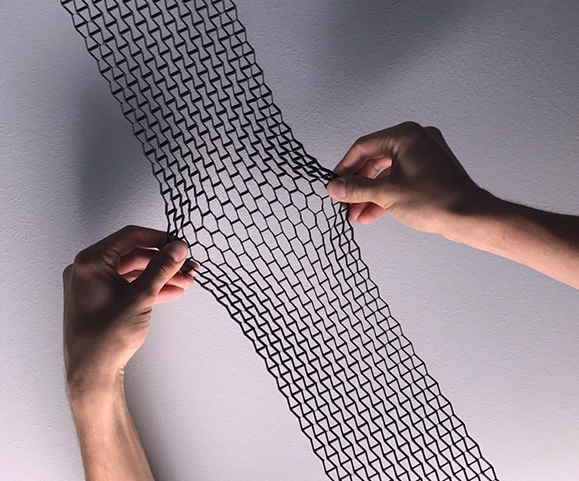

There are some pictures and diagrams below, but the idea is that when force is applied the material structure expands. So, I immediately jump to how this can be applied to fencing? I ended up looking into the chest protector as this technology is already being explored in cycle helmets, running shoes and in the military, due to its protective and flexible properties.

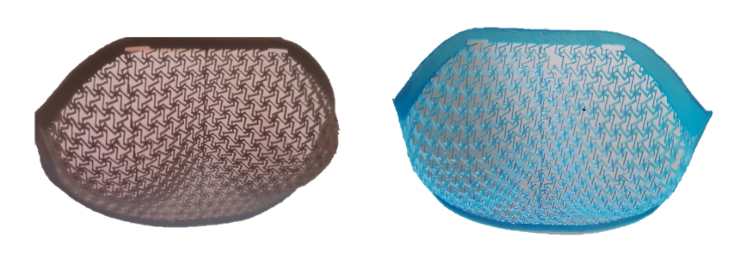

I spent 6 weeks exploring these patterns and materials and attempting to apply them to the chest protector. My most successful prototype can be seen photographed below. Due to the detailed intricate patterns, computer capacity was the biggest struggle. As I was unable to make the mesh smaller, the holes are too large to be an effective product and made it hard to carry out any realistic tests. This project still needs a lot more work to carry out the appropriate testing and perfecting the design. This is a very new technology so there aren’t huge amounts of existing research, but as more and more is being discovered, hopefully new solutions will arise that can be utilized.

But even after all this time spent working on this product, I was still interested and still hopeful that one day there would be a better alternative to what’s on the market for women. Since working at Leon Paul, I have been given the freedom to work on the chest protector again. I know this isn’t going to be easy as I would like to produce a product that is not only protective but stylish and meets the needs of the women wearing it. Whilst working here, I have been exposed to interesting new materials and technologies that I look forward to working with and can’t wait to tell you all about the first test products soon.